Your cylinder may be looked after and look fine on the outside, but unseen damage and contaminants can build up inside regardless of how well you look after it.

Regular servicing of your cylinder will ensure it is safe to use.

Cylinder valves can collect debris over time, this can, in turn, damage your gun if used for air rifles, or your regulators if used for diving. During the servicing we check the valves as well as the cylinder.

It is a requirement to have any compressed gas bottles such as your Scuba Diving and Air Gun Cylinders periodically tested.

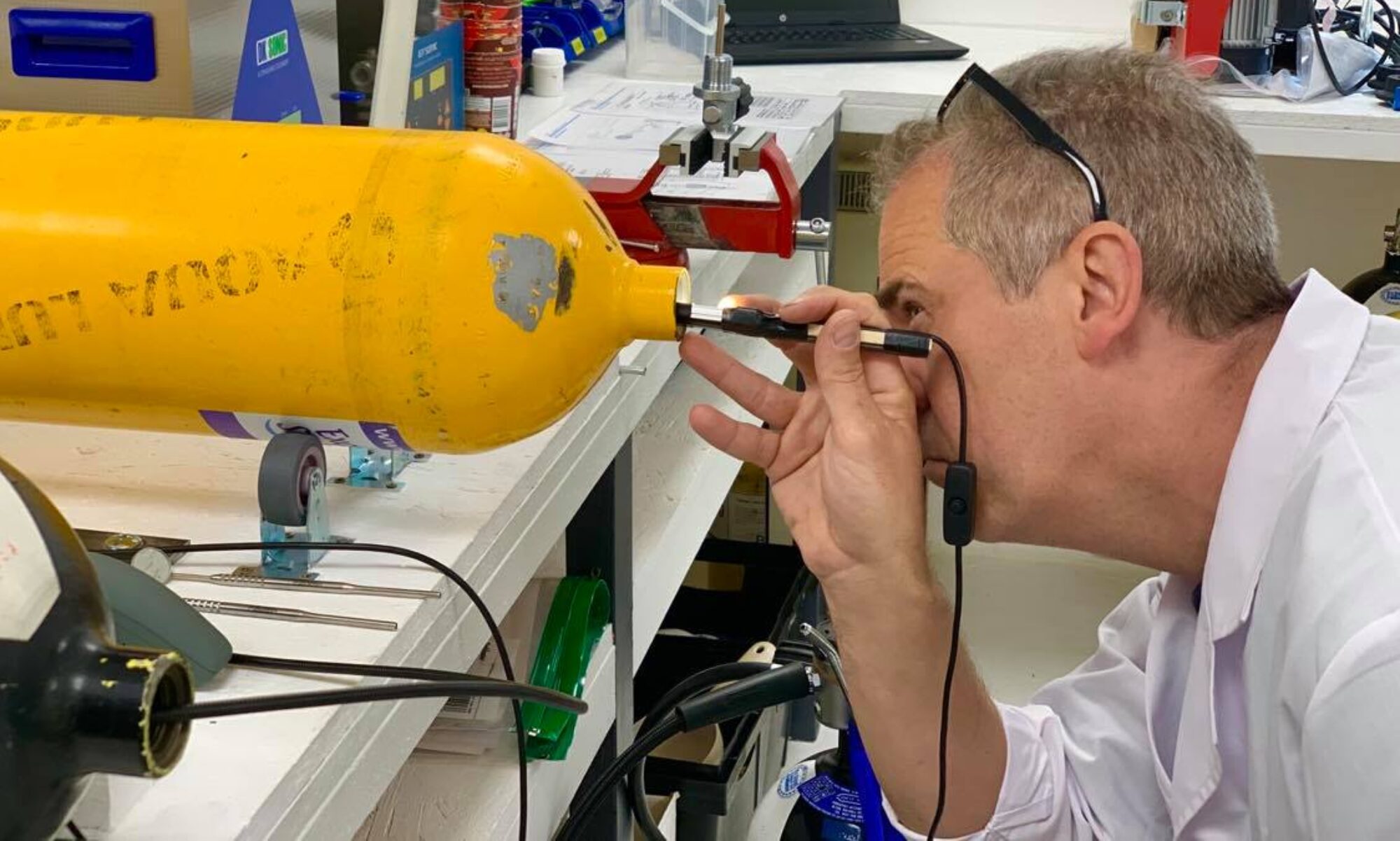

Visual inspection

A visual inspection (visual) and valve service is required within 2 ½ years from the date of manufacture or the last hydrostatic test.

Hydrostatic test

A hydrostatic test (hydro) and valve service is needed every 5 years from the date of manufacture or if a visual test date has been missed.

Diving Cylinder Testing

Diving cylinders must have the following inspections:

- Visual Inspection – every 2.5 years

- Hydrostatic Inspection – every 5 years

- O2 Clean – every 15 months – if you intend to use enriched air in your cylinder it is recommended to have your cylinder O2 cleaned.

Gun & Paintball cylinder Testing

Gun cylinders must have the following inspections:

- Hydrostatic Inspection – every 5 years

Industrial cylinder testing

Industrial cylinders must have the following inspections:

- Hydrostatic Inspection – every 10 years

All Cylinder Testing for Scuba Diving and Air Gun Cylinders will have an air or nitrox fill included in the service.