It is important to look after your cylinder, regardless of what you use it for, in both handling it as well as storage. It is not possible to see the inside of your cylinder, however many things can lead to damage on the inside, including how you store a cylinder.

Cylinders have been designed to exceed stringent performance and safety standards, it’s up to you to ensure that your cylinder is always kept in peak condition by carefully following these recommendations for continued care and maintenance.

Neglecting your cylinder and it could result in irreversible deterioration and a potential threat to personal and other people’s safety.

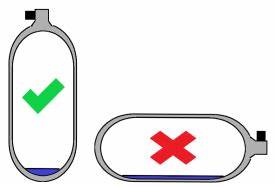

Don’t store the cylinder in a horizontal position!

At a dive site, your main concern is that the cylinder shouldn’t fall over. In storage, however, you can easily secure a cylinder in an upright position, which you should! What we want to avoid is the corrosive damage to the aluminium from the humidity inside the cylinder. This makes the stand-up position better for three reasons:

- If the cylinder lays down, the small amounts of water inside the cylinder will cover a larger surface. This will put a bigger portion of the inside at risk of rust than if the cylinder is standing up.

- The aluminium is thicker on the bottom of the cylinder than on the sides. This means that the bottom can withstand more corrosion before it compromises the strength of the container.

- Corrosive damage on the bottom is easier to spot during inspections, when compared to corrosive damage on the sides.

Leave the right pressure inside the tank

It might seem to make sense that emptying the cylinder completely for storage should lessen the “load” on the materials. This, however, is wrong. A small positive pressure inside the cylinder will help keep small particles and humidity from entering the cylinder. Too much pressure, on the other hand, will increase the partial pressure of oxygen, speeding up corrosive damage.

So what’s the right amount of pressure? For a cylinder in long term storage (defined as more than 90 days), some cylinder manufacturers state that the maximum pressure should be 300 psi (20 bar). Other manufacturers say that the optimal pressure is 100 psi (3 bar). Since most gauges don’t measure pressures as low as 100 psi (or 3 bar), we suggest you make sure that the pressure is as low as your gauge measures, as long as you know it’s below 300 psi (or 20 bar), but NOT empty!

Note: — A cylinder expands every time it is filled and contracts when emptied. Repeated expansion and contraction fatigues the metal and eventually it will fail. This is why we do hydro testing every year, to detect cylinders that no longer tolerate repeated expansion/retraction.

Avoid heat, temperature fluctuations and humidity

The materials that make up your cylinder expand when they heat up and contract when they cool down. The same is true for the air inside. In high temperatures, the pressure will rise, and in low temperatures, the pressure will decrease. These fluctuations wear on the materials and therefore a cylinders should be kept in a place with a fairly constant temperature. High temperatures can cause serious damage to the cylinder, as the materials can weaken in the heat while the pressure of the air inside increases dramatically.

Humidity in the air or on the surface below the cylinder could cause corrosive damage onto the outside of the tank. Materials such as wood and naked concrete can hold humidity and are not optimal as a surface material for underneath a cylinder.

Store the cylinder in a dry and cool place without any significant local heat sources.

Make sure you have rinsed your cylinder

After diving (especially in salt water), make sure to rinse the cylinders thoroughly with fresh water in order to remove any dirt and minerals, which can accelerate corrosive damage. If your cylinder has a boot, make sure to remove it every once in a while to rinse this area as well.

Rinsing, of course, needs to be done after every dive, but is extra important before a long-term storage.

Take good care of your cylinders during use and transport

For anyone who uses cylinders, make sure to handle them correctly when not in storage. It’s important that you don’t get water into them, damage them in transport or when topping up with air. Make sure to close your cylinder properly so no air can get in, especially when you store your cylinder for a while.

Cylinder maintenance

Do checks! This is for any cylinder, regardless if you use it for diving or paintballing, shooting etc.

- If your cylinder has been stored for longer than 90 days

- If the air you breath in tastes odd

- If the air that comes out of your cylinder smells odd

- If you have significant rust on the outside

- If your cylinder has been stored empty

- If your cylinder has emptied during storage

- If you bought a 2nd hand cylinder – at minimum check all test dates on the cylinder!

- If your cylinder is leaking

- Do not leave cylinder valves open after use. This allows moist-air intake that can cause internal corrosion.

- Regularly remove the cylinder from its backpack and the boot for a more thorough cleaning

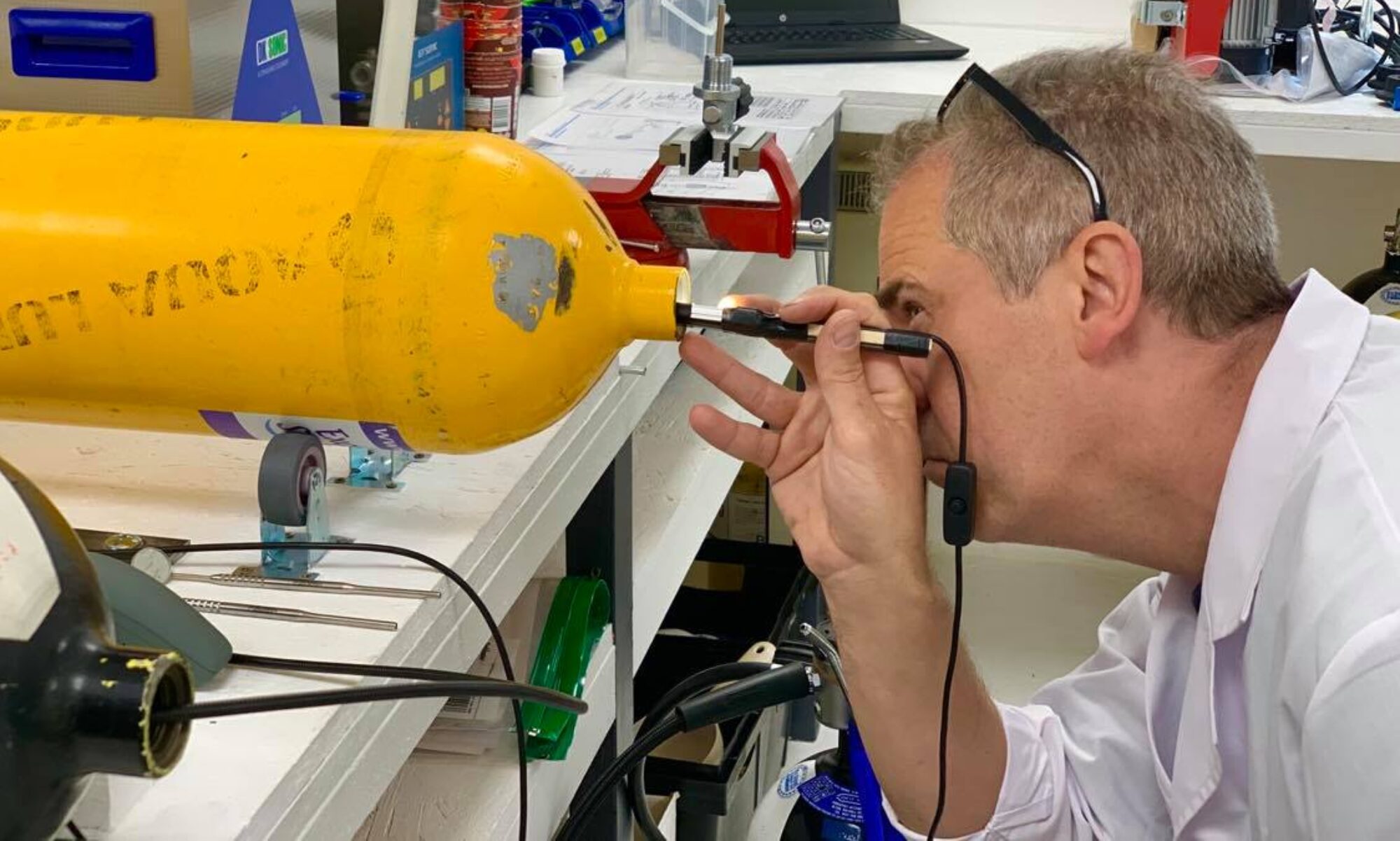

Check out some of the photos of the inside of cylinders, including those still within inspection date!